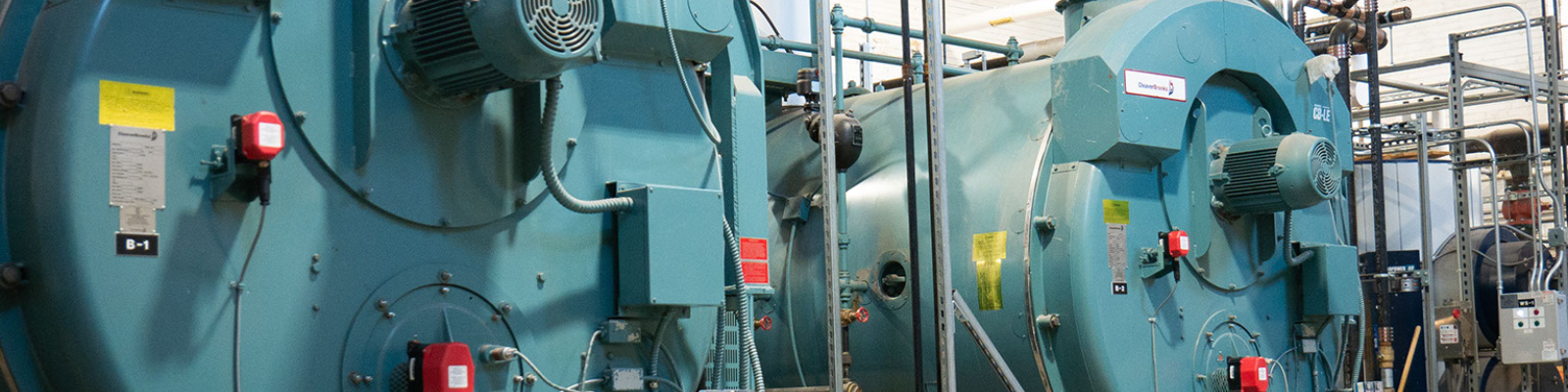

Delval can design, engineer, specify, and provide a complete chemical feed and control system for your Boiler. We have installed chemical feed systems that eliminate drums and daily testing. Our installation record has over 150 chemical feed and control systems of varying shapes and sizes in place and operating successfully. We have the expertise to fully integrate it with the building management system.

Our control system makes chemical feed hands-free and monitors all parameters in the boiler system 24/7/365. Chemical pumps are activated to meet the demand for chemical, thus ensuring the treatment levels protect the boiler system.

Configuration, start-up, and training is included in all equipment provided. The majority of the equipment is warrantied for two (2) years. Maintenance of the chemical feed and control equipment is included in Delval’s water treatment programs or can be purchased separately as well. Installation can be included and is always optional through Delval’s mechanical team for all equipment.

Automated Surface Blowdown Control

We offer a fully integrated stand-alone automated surface blowdown station for up to four (4) boilers. The equipment is mounted on a plexiglass board which is on struts for anchoring to the floor. So, the installer only needs to connect the inlet to a surface blowdown line coming off the boiler and the outlets go to drain. Also, the wall mount unit can be located on the floor away from the boiler for easy calibration, testing & maintenance. Figure 1 is a sample unit below…

All readings and settings are local to the unit but can be sent to the building management system via Modbus or BACNet. All equipment can be purchased separately and plumbed in the field as well.

Delval will start-up and configure the surface blow-down controller whether it is on a wall mount blowdown station or individually mounted for operation. Training and operating manuals will be provided for the operators on the automated surface blowdown controller system. Additionally, we’ll service the automated surface blowdown system whether new or in operation in conjunction with or separate from our treatment programs.

Solid Feed

Solid feed programs eliminate all the costs and handling related to liquid drums. The products come in 11# jugs. The jugs are inserted in the solid feed station. Figure 2 below is a four (4) station boiler solid feed system…..

The metering pump on the pump shelf below the feed station is activated to send the liquid solution to either the feed water tank, deaerator, feedwater line or boiler. The metering pump can be activated by make-up water demand, feedwater demand or timers. Feed stations can be bought as a prefabricated wall mount unit as shown in figure 2. Or they can be provided individually and mounted in the field.

Once installed, Delval will start-up and configure the solid chemical feed stations. Training and operating manuals will be provided for the operators on the solid feed system. We can service the solid feed system whether new or in operation in conjunction with or separate from our treatment.

Liquid Feed

Liquid feed stations are the predominant method of applying for a boiler water treatment program.

Our simplest form of liquid feed is to place a metering pump on the drum of the neat liquid products being fed thus the term “neat” feed for this approach. The number of metering pumps is directly proportional to the number of feed points and the number of products being used.

The preferred liquid feed system is to employ the use of mix tanks in which the liquid treatment products are mixed to homogeneous cocktails using an agitator.

Our preference for cocktails versus neat feed has its foundation in maintenance, chemical control, flexibility. Adjusting a liquid treatment program using a cocktail of the individual products provides better control flattening both the peaks and valleys of chemical residuals which are critically maintained in given ranges to protect the boiler system.

We will size and provide mix tanks with agitators whereby batches would last a minimum of one (1) week. Mixing the cocktails can be manual, semi-automatic or fully automatic. We design, engineer, and provide a fully automated hands-free system that allows the cocktail to be created when needed whereby the operator simply “flips a switch” to activate the process.

We can provide double-walled containment tanks or smaller tanks with containment to store neat products safely tanks. Additionally, provide transfer pumps to move the neat liquid from either a drum or double-walled containment tanks to the mix tanks.

Automated liquid chemical control feed system eliminates daily testing and maintains chemical residuals that are necessary to protect the boiler. In addition, the control system monitors and displays via a touch screen monitor the following boiler control measures:

- Conductivity of each boiler

- Condensate return

- Make-up water demands

- Feedwater demands

- Cycles of concentration

- Individual amounts of chemical used

To fully utilize the power of the Delval control system requires feed water meters on each of the boilers.

Once installed, Delval will start-up and configure the liquid feed system. Training and operating manuals will be provided for the operators on the feed station(s); its workings; and troubleshooting. We’ll service the liquid feed system whether new or in operation in conjunction with or separate from our treatment programs as needed or on a preventive maintenance plan at an agreed upon frequency.