Industry: Healthcare

Company: VA Hospital in Altoona, PA

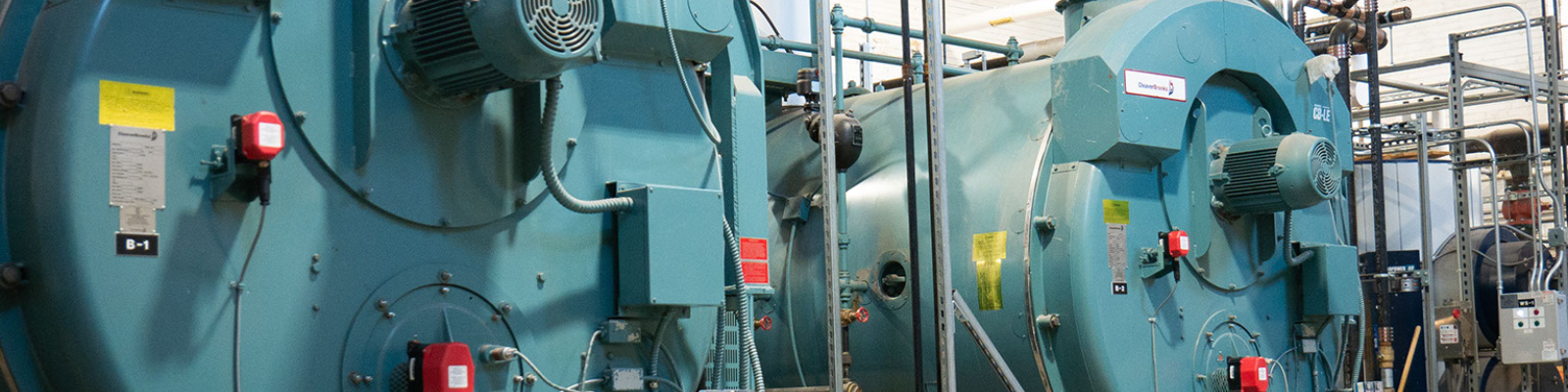

Equipment: (3) Model 4WI 400 horsepower Firetube Boilers with Economizers, Hawk Control 4000 with Masterpanel and Deaerator

While functioning solidly and reliably for 40+ years, the Cleaver-Brooks steam boilers at a major VA hospital were due for replacement. The hospital desired to replace the boiler equipment that would maintain the proven reliability they were accustomed to. Advancements in boiler technology will also deliver greater efficiencies that would save fuel and resources.

Delval Equipment partnered with an engineering firm that championed the mechanical room design and a general contractor to meet the stringent timeline. Delval Equipment supplied the new boiler room equipment and handled the startup. It was imperative the project team ensured uninterrupted operation for the hospital to continue its day-to-day functions.

Dedicated Project Manager

Because the hospital has such critical functions and the timeline was tight, Delval Equipment assigned a full-time start-up manager to oversee the complex project to ensure the project went as smoothly as possible from start to finish. The hospital boiler operator, Brady Kissel stated, “there were no issues with start-up – working 12-hour days they brought the boiler plant online as scheduled.”

Kissel, is very pleased with the new equipment saying, “I have been in the boiler operator business for over 30 years – that started in the US Navy. Been around all kinds and names of boilers. My pick of the boilers would be Cleaver-Brooks boilers.”

Improved Boiler Efficiency and Reliability

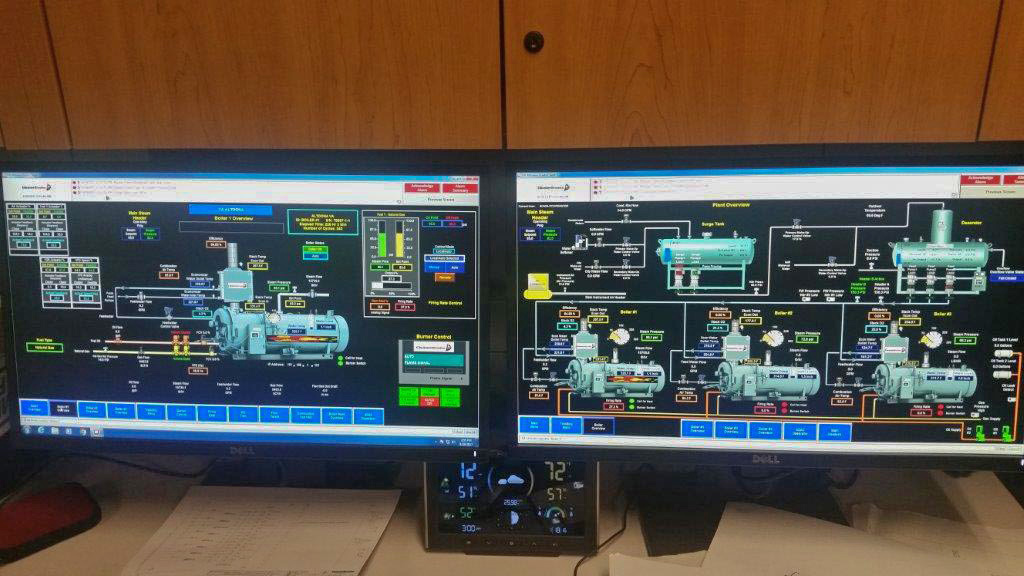

A facility that was operating 40+-year-old equipment will receive immense efficiency and energy-saving gains updating their boiler equipment utilizing the latest technology. The Cleaver-Brooks firetube boilers have integral burners delivering greater combustion efficiency. Kissel noted “the overall efficiency averages around 85% (which is great for a high-pressure steam application) and we have the flexibility to switch to oil.” The boiler economizers reduce energy by capturing waste heat to preheat boiler feedwater. And the Hawk Control system with SCADA package allows you to monitor the system remotely and view boiler status and trends. Kissel added, “the control has a great graphical interface with equipment pictures that allows you to change set points on control valves and etc- it’s very easy!”

Resource reduction also comes in the form of electrical usage, not just fuel. The pumps and blower motors all function on variable frequency drives saving electricity.

Check out the gallery for before and after pictures.