Background

Definitions & Terminology

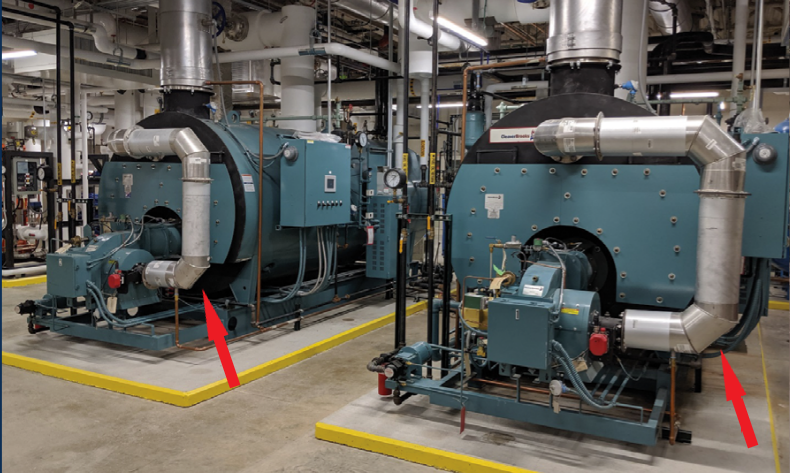

Combustion Unit:

Stationary equipment used to burn fuel primarily for the purpose of producing power or heat by indirect heat transfer.

Flue Gas Recirculation (FGR):

The process of returning a percentage of the flue gas of the boiler to be mixed with the combustion air and fuel in combustion in an effort to reduce NOx by reducing peak flame temperatures and lowering the average oxygen content of the combustion air. FGR can be accomplished through the use of an additional fan to recirculate the flue gases back into the flame or by using the combustion air fan to induce (IFGR) the recirculation flow.

Gas-Fired Boiler:

Any boiler that burns gaseous fuels not combined with any solid fuels and burns liquid fuel only during periods of gas curtailment, gas supply interruption, startups, or for periodic testing, maintenance, or operator training on liquid fuel.

Natural Gaseous Fuel:

- Natural gas, a naturally occurring mixture of hydrocarbon and non-hydrocarbon gases found in geologic formations beneath the earth’s surface, of which the principal constituent is methane; or

- Liquified petroleum gas, as defined by the American Society for Testing and Materials in ASTM D1835 (incorporated by reference, see § 63.14); or

- A mixture of hydrocarbons that maintains a gaseous state at ISO conditions (i.e., a temperature of 288 Kelvin, a relative humidity of 60 percent, and a pressure of 101.3 kilopascals). Additionally, natural gas must either be composed of at least 70 percent methane by volume or have a gross calorific value between 35 and 41 megajoules per dry standard cubic meter (950 and 1,100 Btu per dry standard cubic foot); or

- Propane or propane-derived synthetic natural gas. Propane means a colorless gas derived from petroleum and natural gas, with the molecular structure C3H8.

Small Combustion Unit:

A combustion unit with a rated capacity equal to or less than 100 million Btu per hour of heat input fueled by gaseous fuel, or by No. 2 or lighter (viscosity less than or equal to 5.82 cSt) commercial fuel oils.

Source:

An air contamination source.

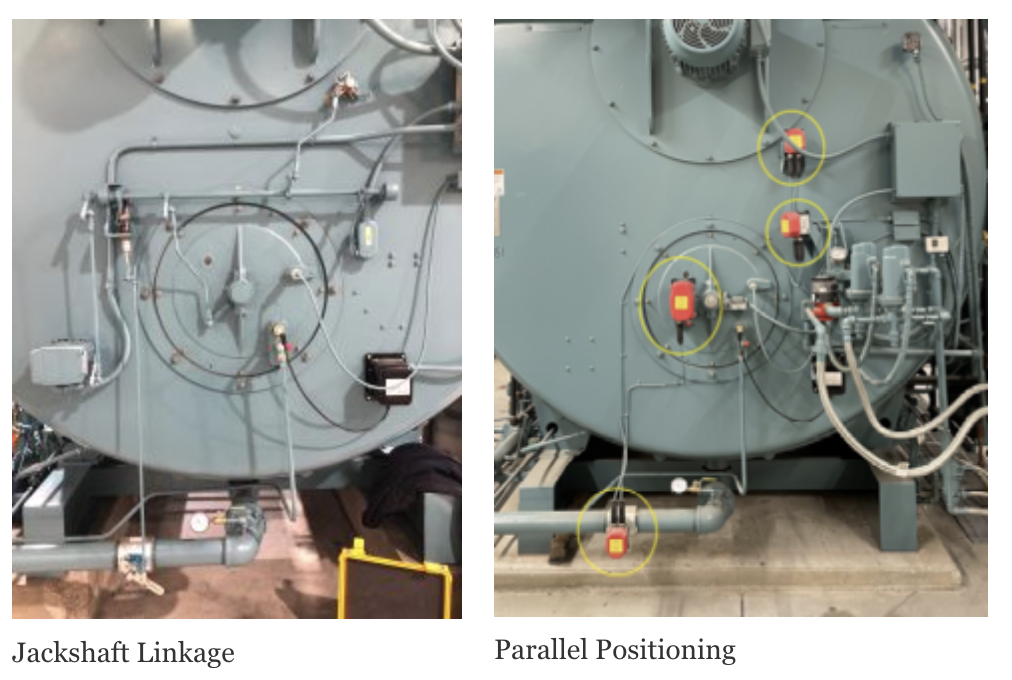

Burner Control Technology:

- Single-Point Positioning, also known as jackshaft, is a burner control scheme that utilizes a single positioning motor connected to a jackshaft that is mechanically linked to the various valves and dampers that control combustion. The controlled components typically include the combustion air damper, fuel valves, and FGR damper.

- Parallel Positioning, also known as linkage-less, is a burner control scheme that utilizes positioners on each of the controlled components to independently adjust each input to precisely control combustion.

Burner NOx Emissions Levels:

- Uncontrolled – when there are insufficient means utilized to limit the emission of NOx to any particular level.

- Low NOx – when a combination of burner technology and combustion controls are implemented to reduce the limit of emission of NOx to below 30 ppm.

- Ultra-Low NOx – when a combination of burner technology and combustion controls are implemented to reduce the limit of emission of NOx to below 9 ppm.

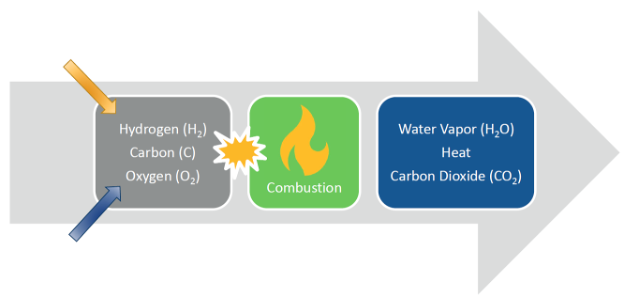

Combustion Basics

As it pertains to boilers, combustion is the chemical reaction that occurs when a fuel, typically

comprised of hydrocarbons, is combined with oxygen and ignited to produce heat. The emissions of the

combustion of standard fossil fuels is Carbon Dioxide (CO2 ), Carbon Monoxide (CO), Nitrogen (N2 ),

Nitrogen Oxide (NOx ), Sulfur Oxide (SOx ), Oxygen (O2 ), Water (H2O), Volatile Organic Compounds (VOC), and Particulate Matter (PM). The amount of each pollutant is dependent upon the exact composition and cleanliness of the fuel as well as the efficiency and precision of combustion.

Effects of Pollutants

Nitrogen Oxides (NOx)

The major concern with NOx is the resultant reactions that are initiated by its presence. The first of

these are the reactions that result in ground-level ozone. Additionally, other reactions initiated form

particulate matter (PM2.5) as well as acid rain.

Carbon Monoxide (CO)

Carbon monoxide is a colorless, odorless gas that is a result of incomplete combustion. CO binds to

hemoglobin in the blood, which prevents oxygen from being transported to organs and tissues. This is

why CO poisoning starts with headaches, dizziness, nausea, and confusion but at high levels and

prolonged exposure can result in death. CO also contributes to the formation of ground-level ozone and

smog.

Sulfur Oxides (SOx)

Sulfur oxides are the result of the combustion of fuels that contain sulfur. The amount of sulfur oxides

are linked directly to the amount of sulfur in the fuel so the best prevention is to utilize fuels that

contain very little to no sulfur. Sulfur oxides are a concern because they react with other compounds in

the atmosphere to form acid rain.

Volatile Organic Compounds (VOC)

Volatile organic compounds are typically the result of poor or incomplete combustion due to burners

that were not set up or tuned properly. VOCs are a family of chemicals containing carbon, hydrogen,

and sometimes oxygen that are evaporated easily into the air. The major concern is their role in the

formation of ground-level ozone. Health hazards are also associated with VOCs with symptoms like that

of carbon monoxide.

Particulate Matter (PM)

Particulate matter is a mixture of different types of solid and liquid compounds including nitrates,

sulfates, carbons, oxides, as well as un-combusted elements in the fuel provided to the burner. The

major concern is related to the impact on human health and has been linked to many issues including

respiratory problems, cardiovascular disease, and cancer.

What is the GP-1 and Who Needs One?

The Pennsylvania Department of Environmental Protection (DEP) maintains a regulatory General Permit program to regulate air contamination sources in several industrial categories, including small boilers, burn off ovens, storage tanks, lithographic printing, mineral processing, petroleum dry cleaning, powder metal sintering furnaces, and natural gas production. The General Permit program, along with the Best Available Technology (BAT) provisions was established in 1994. Currently, the DEP has ~20 air quality General Permits, each having a specific scope and application.

The GP-1 has been developed under the authority of Section 6.1 (f) of the APCA (35 P.S § 4006.1(f)) and under Section 504(d) of the Clean Air Act (CAA) (42 U.S.C. § 7661c(d)). This particular regulation is dual purpose used for both a pre-approved plan approval and as an operating permit for a specific category of sources. Any facility owner or operator that is planning to install and/or operate a small combustion unit that is within the scope of the GP-1 is required to submit the form for General Plan Approval or General Operating Permit.

Link to PA DEP General Permits:

https://greenport.pa.gov/elibrary/GetFolder?FolderID=758154

Summary of 2023 Changes for PA GP-1

While the primary change that will be noticed is the reduction of the emission rate of NOx and CO, there are other significant changes that are captured in the table below. These changes include increasing scope of the permit by increasing the upper limit of the input from 50 MMBtu/hr to 100 MMBtu/hr, as well as the annual tuning and reporting. Another major change is the revision to the fees associated with the various activities.

| Item | Previous GP-1 | Revised GP-1 |

| Scope | 10 – 50 MMBtu-hr | 10 – 100 MMBtu/hr |

| Emissions Rates | Natural Gas: 30 ppm vd NOx @ 3% O2 2 Fuel Oil: 90 ppm vd NOx @ 3% O2 Either Fuel: 300 ppm vd CO @ 3% O2 | Natural Gas: 9 ppm vd NOx @ 3% O2 2 Fuel Oil: 90 ppm vd NOx @ 3% O2 Either Fuel: 130 ppm vd CO @ 3% O2 |

| Testing | Within 180 days after initial start-up | For non-gaseous fuel fired boiler with capacity > 50 MMBtu/hr: Within 180 days after initial start-up & re-authorization (every 5 years) |

| Reporting | Per 25 Pa. Code Chapter 139 | Emission Report & Compliance Certification Annually |

| Fees | $375 Every 5 years, or for any modification | $1,600 – General Plan Approval Application Fee $750 – General Operating Permit Application/Renewal Fee $500 – Annual Operating Permit Maintenance Fee $500 – Transfer of Ownership Fee $500 – Administrative Amendment Fee |

Impact of Changes

Existing Equipment

In order to capture the units that are now included in the scope of the GP-1 (those in the 50 – 100

MMBtu/hr), a change was made to require source testing on non-gaseous fuel-fired equipment. This

change does not apply to any non-gaseous fuel-fired combustion unit that has an input of 50 MMBtu/hr

or less nor does it apply to units in the updated scope that are fired on gaseous fuel. However, there are

additional work practices, reporting requirements, and fees that must be accounted for.

First, boilers must be tuned annually. With this tuning, it is a great idea to align with yearly preventative maintenance which would consist of shutting down and opening the boiler to clean and inspect the fireside, waterside, burner, piping, components, and miscellaneous systems.

The cleaning and inspection will give insight into how the boiler is operating and any changes that need to be made, as well as give indications of issues or problems before they become a failure! A yearly service will increase

safety, efficiency, and operational reliability while also decreasing downtime due to unexpected failure.

When everything is put back together and closed up, the tuning can be performed to ensure the burner

is properly adjusted based on any changes to the system and environment. Ideally, in areas with

changes in seasonal weather, a burner tuning should be performed at least twice a year since the

properties of the combustion air are so different between the winter and summer months.

Additionally, these tunings and combustion compliance reports need to be submitted to the DEP to

ensure continual compliance with the emission regulations of the permit. Along with the additional

work practices come increased and additional fees that cover the various renewals, changes, or

transfers that may happen over the life of the permitted equipment.

It is important to note that, at this time, the DEP has approved no requirement for compliance with

updated emission regulations for existing equipment. While this may change in the future, Delval

Equipment has not received any indication that this will change for the foreseeable future. Therefore,

currently permitted equipment does not need to be retrofitted to comply with the revised emission

regulations. But, if your facility would like to self-regulate and change its environmental impact, our

team at Delval would be happy to speak to you about your project!

How to Prepare

New Work Practices & Reporting

As discussed, source testing will be required for new and re-authorized GP-1 permits for combustion units that are fired on non-gaseous fuel (commercial fuel oil) and are greater than 50 MMBtu/hr. For all other units, the DEP is relying upon manufacturer guarantees and annual tune-ups with portable analyzers and combustion reports to prove compliance with the requirements. This approach is a result of the proven technology available to easily meet the more stringent requirements and reduce the environmental impact of new equipment being installed in Pennsylvania.

Keep in mind, that the records of inspections, tunings, and associated boiler work must be kept for a minimum of 5 years. This is important because if the DEP concludes that the portable analyzer data is not sufficient to demonstrate that the combustion unit is in compliance with the regulation, additional details and/or testing may be requested.

Aligning Current Project Pipeline

For all current and future projects, ensure that all specifications are written for the updated emission regulations. This will also mean that the products used for the design basis should be reviewed to ensure they are able to meet the requirements. When ineligible products are found, they should be replaced with equipment that is able to meet the new GP-1 without sacrificing quality, reliability, safety, or efficiency.

But you may ask, how can I do that?

Well, let’s give you a few things to look out for:

- Pricing Impact – With the proven technology on the market today, when purchasing a new boiler, roughly a 10-15% price increase can be expected to go from 30 ppm to 9 ppm NOx when firing on natural gas. This is due to the utilization of many core technologies that have been developed and tested over many years. Given the very strict regulations in other areas of the country, boiler and burner manufacturers have been working on these products for many years with many successful installations. The use of FGR, staged combustion, and burner design have made ultra-low NOx emission widely achievable and economically feasible.

- Performance Impact – The primary method of NOx reduction in combustion is related to the reduction of the flame temperature. Since the rate of heat transfer decreases with a decrease in temperature differential this means there is expected to be a small reduction in thermal efficiency. Still, with technological development, this efficiency loss is kept to a minimum and minuscule in comparison to the pollutant reduction for the environment. However, one criterion that is to be mentioned is the turndown of the burner on ultra-low NOx burners. As a result of the burner design and methods of NOx reduction used, there is expected to be a reduction in the turndown capabilities. Be sure to understand the effect on a particular boiler and burner package will have on turndown and look for verified numbers for site-specific operating conditions and requirements. No facility owner will be happy when the promised data and actual data are so different that an equipment derate or replacement is required!

- Fuel Firing – Another consideration is to ensure that the fuel-firing requirement of the facility matches the fuel-firing capability of the equipment. Some ULN burners are not able to fire commercial fuel oil, even as a secondary fuel. If the site requires dual fuel capability (NG & #2 oil, for example) be sure that the equipment selected for the basis of design is able to run on both.

- Mesh Style Burner Head – One of the burners that is easily capable of achieving ultra-low NOx values utilizes what is called a mesh head. One of the selling points is that this burner is able to achieve 9 ppm without FGR! This may seem like a positive but some of the drawbacks of this particular technology should be well understood. Those drawbacks consist of: high O2 (which is high excess air – reducing efficiency), natural gas only, and the safety concern of the mesh head requiring regular checks and maintenance. With a mesh head, a pre-mix of fuel and air is pushed through the mesh where combustion happens on the surface. One of the operating principles is that the speed of the flame is less than the speed of the pre-mixed products being fed into the burner head. If the mesh was to fail (crack, break, or be damaged) the flame is then able to propagate back into the burner head where the fuel is mixing. Regular checks and maintenance should be performed with any burner utilizing a mesh head with these safety concerns in mind. While there are applications for each burner style be sure that each decision is based on the correct product for the application.

- Guaranteed Performance – With the performance impact already mentioned, look for products that are able to guarantee performance across the firing range. Some boiler and burner packages are able to guarantee 3% O2 across the firing range while meeting the 9 ppm NOx requirement. Also, look for turndown values that are based on the site-specific application and operating conditions!

In summary, there have been significant changes to the PA GP-1 including the upper limit being extended to 100 MMBtu/hr, natural gas emissions are reduced to 9 PPM and additional requirements for annual tune-ups and reporting. Delval Equipment currently offers proven equipment and support that aligns with the parameters of to comply.

We can help! For questions or support contact Delval Equipment.