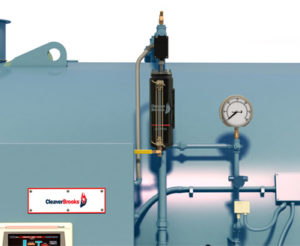

RWF Single Loop PID Controller (Part of Siemens’ Modulating Water Level Control System)

- Adjustable PID parameters for precise level control

- Built-in 24 VDC power supply for transmitter power

- Set-point/parameters are adjustable

- Bright display of set point and actual level

- Two configurable built-in relays

- Optional ModBus

- Password protection of programmed parameters

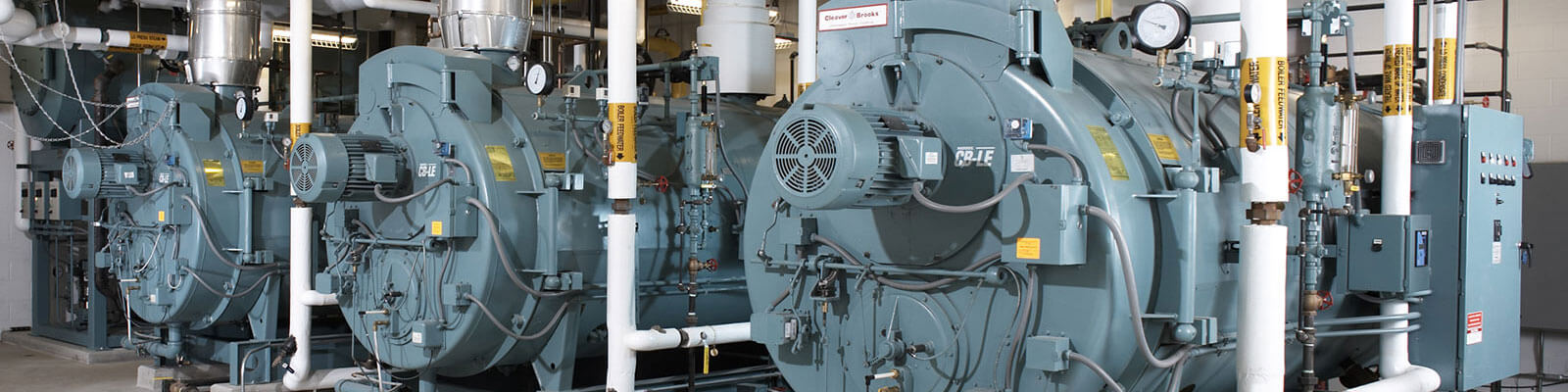

The Siemens Electronic Water Level Control System sets the standard for maintaining accurate water level in boiler steam drums, deaerating feed water tanks and condensate return tanks. The control system consists of a “SMART” differential pressure transmitter fitted with a 3-valve manifold, an application specific single loop PID controller and an electrically actuated ANSI 250 control valve assembly. The Siemens Electronic Water Level Control System provides precise water level control while ensuring efficient and reliable operation.

Key Features and Benefits

- 100% solid state system

- More efficient boiler operation

- Minimal boiler water carryover

- Reduced thermal shock to boiler

- Reduced feed water pump wear

- For boilers with rapidly fluctuating steam load changes, the system has the capability to include dual-element control, minimizing boiler drum swell and shrink effects.

- Ease of installation and commissioning

- Digital display of set-point and actual level

- Local adjustment of set point via key strokes

- Three levels of password protection

- Local/manual control options

Accurate feed water control is crucial for efficient, reliable boiler operation. Too low of a water level will expose boiler tubes to overheating, possibly damaging them. Too high of a water level can cause water carryover. The Siemens Electronic Water Level Control System maintains a consistent water level that minimizes these potential concerns.