The system connects to up to 8 Hawk equipped boilers, master panel and ADAC systems on the same Ethernet network and pulls data in from each. Replicates the boiler overview display, Burner Management display, trends, boiler user analog inputs and run data. Allows user to write to a Master Panel to set lead lag sequence, on-off points and system header set point.

Features:

- Remote monitoring on a pre-configured PC

- Data logged to Sequel Database

- Reports for fuel use and runtime hours per fuel for shift, day, week, month and year available

- Developed using Rockwell Automation Factory Talk SE software

- Custom applications available

- Collects raw data required for EPA Area Source Rule and generates reports

- Alarms generated in Hawk systems displayed and kept in history separate from Hawk system

- Configurable IP address to integrate with customer’s network

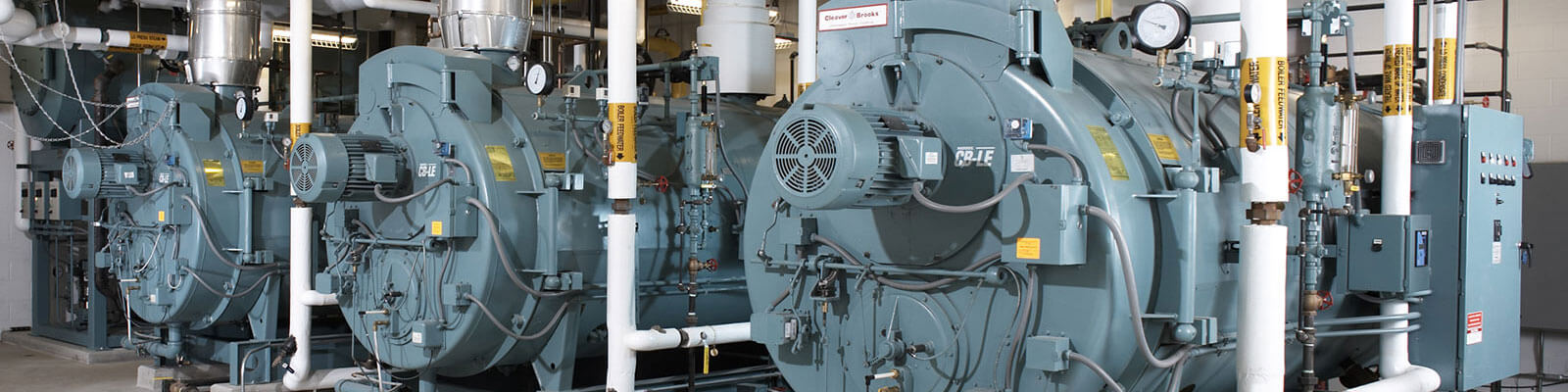

Cleaver-Brooks

Cleaver-Brooks is the industry leader in providing energy-efficient, low-emissions boiler room products. With the power of total integration, only Cleaver-Brooks can offer a complete boiler room solution that is designed, engineered, and manufactured (by one company) to work seamlessly together.

By selecting Cleaver-Brooks, you can forget about having to cobble together a boiler room with different manufacturers and hoping they’ll all work together. Instead Cleaver-Brooks will provide the boiler, burner, controls and all accessory equipment to remove the headaches and provide one source of accountability for your boiler room.

Cleaver-Brooks offers an extensive range of steam boilers from 10 horsepower to 1,000,000 pounds of steam per hour including firetube, industrial watertube, flexible watertube commercial, electric, and heat recovery boilers.