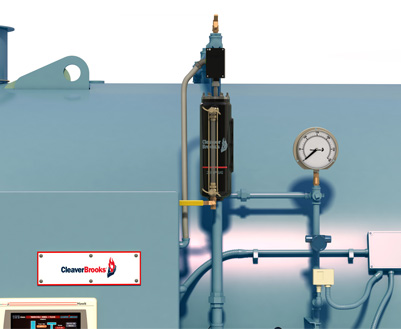

WATER LEVEL CONTROL

The magnostrictive design allows for precise measurement of water level. Advanced technology alerts the operator if the level float is slowing down in relation to normal movement and prompts the operator to perform a water column blowdown. The system also detects if the float has not moved and shuts the boiler’s burner off while time- and date-stamping the stuck float condition. Other information is time and date stamped based on proper or improper routines performed by the operator. Internal system check makes this the safest water level control on the market today.

Features:

- Magnostrictive Level Technology

- Alerts operator to perform water column blowdown

- Detects slow float movement

- Shuts system down on stuck float detection

- Time and date stamps all alarms and blowdown routines

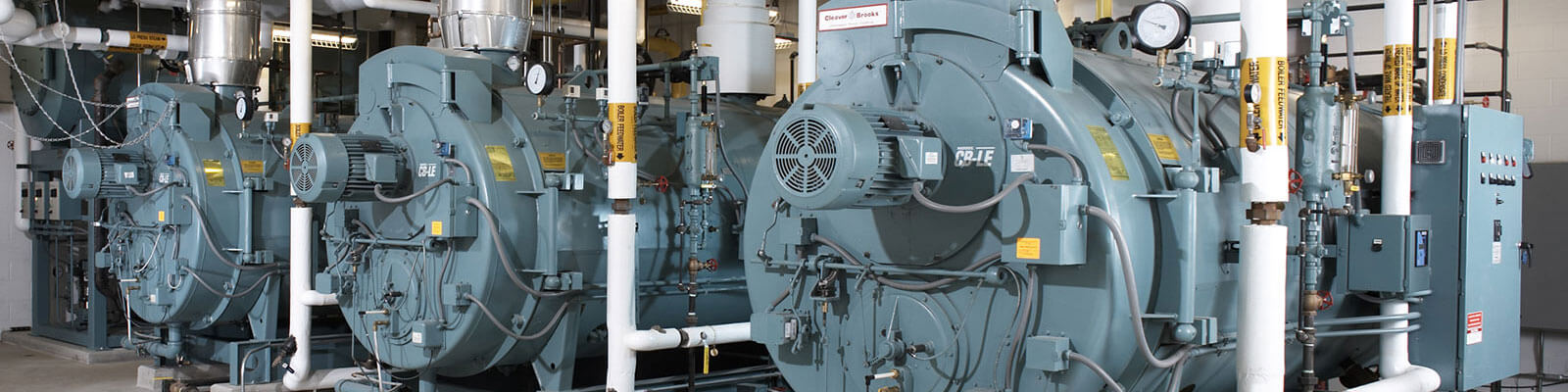

Cleaver-Brooks

Cleaver-Brooks is the industry leader in providing energy-efficient, low-emissions boiler room products. With the power of total integration, only Cleaver-Brooks can offer a complete boiler room solution that is designed, engineered, and manufactured (by one company) to work seamlessly together.

By selecting Cleaver-Brooks, you can forget about having to cobble together a boiler room with different manufacturers and hoping they’ll all work together. Instead Cleaver-Brooks will provide the boiler, burner, controls and all accessory equipment to remove the headaches and provide one source of accountability for your boiler room.

Cleaver-Brooks offers an extensive range of steam boilers from 10 horsepower to 1,000,000 pounds of steam per hour including firetube, industrial watertube, flexible watertube commercial, electric, and heat recovery boilers.