INTRODUCING THE ACCUFEED II

The new and improved modulating valve features an enhanced valve designed to meet ANSI B16.34 specifications, allowing for complete material traceability. This design incorporates a direct coupled motor which utilizes either a 0135 ohm, 0-10 Vde, or 420mA control signal with advanced seal technology and body mount bracket design. This makes for an extraordinarily strong, tough valve capable of handling pressure and unforeseen piping strains with a stem seal that extends operational cycle life and a standardized overall design which keeps parts inventory to a minimum. An improved stem seal design, consisting of live-loaded PEEK and ® thrust bearings and seals, significantly increases valve cycle life over conventional ball valves, and extends time between adjustments. A single Nylon-insert locking nut and four spring washers are used on automated valves.

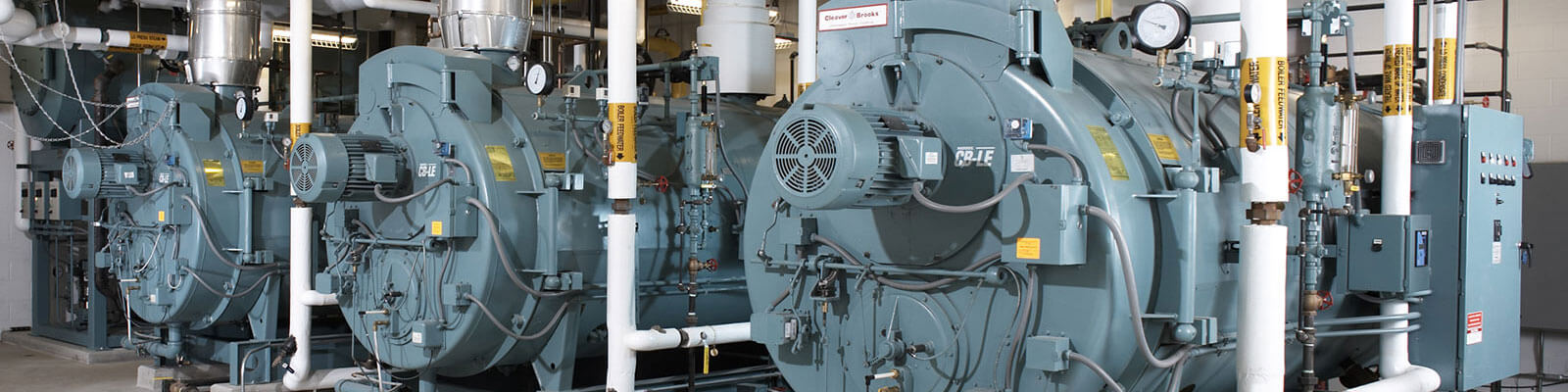

The AccuFeed II sets the standard for accuracy and reliability in maintaining boiler water levels but can also be used on deaerator and other feed water systems. With valve sizing up to 2″, the AccuFeedII can be used on boilers up to 4,800 BHP. The AccuFeed II provides additional installation options. With the modulating continuous system, the feeding of the boiler water is closely matched to the steaming rate of the boiler with a standard or V-Port design, thereby mitigating the stress problem. This metered feeding of the boiler water also provides a more stable water line, fewer (if any) trips, and significantly drier steam due to carryover being better controlled, if not fully eliminated. Modulating Feedwater Valves allow for constant incremental adjustments to feed water into your boiler. Typical applications include, but are not limited to, a 0135-ohm slide wires from a McDonnell and Miller 7b switch or a 4-20 mA.